Newsletter Subscribe

Enter your email address below and subscribe to our newsletter

Enter your email address below and subscribe to our newsletter

Speed, precision, and clean assembly now shape modern production. Light-cured bonding helps on all three fronts. It sets fast under controlled light. It holds tight without high heat. It keeps parts clean and neat.

Teams gain better cycle times and fewer rejects. Designers also have the freedom to create intricate mixes, such as combining glass with metal. The result is lighter products and smoother lines.

This guide explains where UV-curing shines most. You will see clear examples and simple tips. Each section stays practical and easy to apply. Read on to discover how makers across various sectors utilize this technology with confidence.

Tiny parts need gentle handling. UV-curing fits well. It sets in seconds and avoids heat stress. That protects chips, LEDs, and sensors. It also works in tight spaces. Need a quick fix on a flex cable? Cure it in place with a small lamp.

Example uses:

A simple tip: log your cure time, distance, and lamp output. Then repeat those same numbers. Consistency gives repeatable results and fewer field returns.

Ask your team: are we tracking those three settings on every shift?

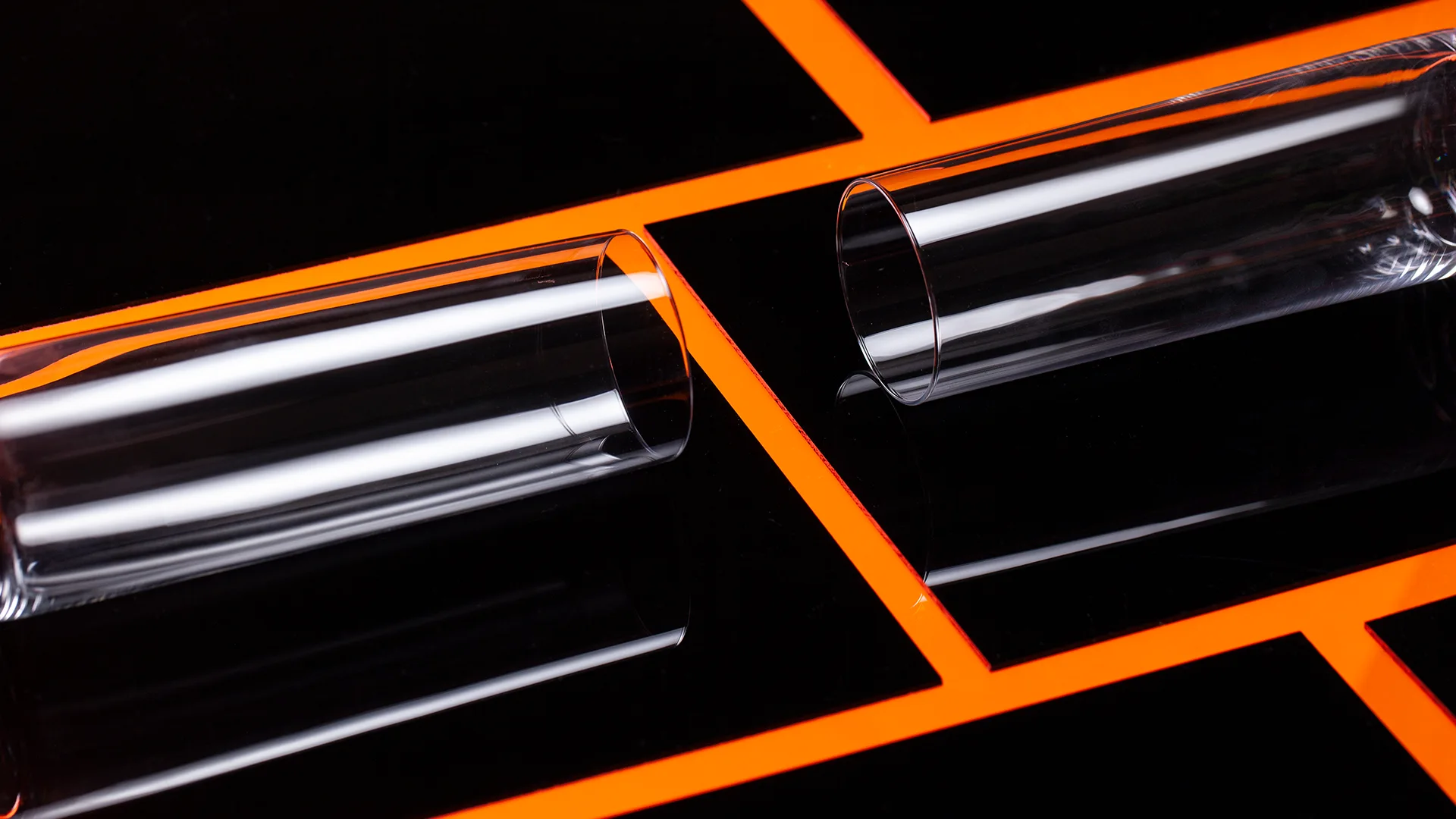

Clear joints are crucial for lenses and displays. Light-activated resin delivers tidy seams with high clarity. It resists yellowing and withstands daily wear. It also bonds glass to metal or plastic. That opens fresh design choices for modern panels and fixtures.

Industrial specialists rely on high-quality glue adhesives that cure under UV light to achieve clear, durable bonds without leaving visible residue. Brands like Permabond develop specialized formulations that maintain optical clarity while bonding glass, metal, or plastic components with precision. These light-cured solutions let makers build sleek, transparent designs for display panels, sensors, and lighting.

Quick check: clean surfaces are non-negotiable. Use isopropyl wipes. Avoid fingerprints before the cure.

Health products demand clean assembly. UV-curing helps because it is solvent-free. It sets fast at low temperatures. That protects plastic parts, such as hubs and tips. Builders use it on catheters, filters, and syringes. Many grades meet biocompatibility needs.

Example: a catheter joint needs no heat and no pressure. Apply a tiny bead, align parts, and cure through clear tubing. The joint reaches handling strength in seconds.

Quality tip:

These habits support audits and speed root-cause checks when issues appear.

Mobility parts face vibration, sun, and wide temperature. Photo-curing forms tough joints without adding weight. Shops use it for sensors on glass, interior trims, and cabin panels. Fast set time keeps lines moving. Jigs release quickly.

A real scene: a windshield sensor bracket must hold right away. Light the joint for a few seconds. The bracket remains in place while the car advances to the next step. No extra clips. No long oven dwell.

Ask your process lead: Can we swap a slow cure step for a light station? If yes, you may gain throughput with minimal floor changes.

Many plants join plastics, coated metals, and composites. Light-cured resin works well across those mixes. It supports automated dots and beads. Robots can place it with high repeatability. The part moves under a lamp and exits, ready for the next step.

Practical wins:

Implementation tip: Start with a pilot cell. Validate pull strength, cure windows, and fixture design. Then scale to parallel lamps. Keep maintenance simple by logging bulb hours and lens cleaning dates.

Clean tech requires durable joints that withstand weather conditions. Photo-curing helps with solar layers, sensor pods, and battery covers. It seals edges while staying clear where light must pass. It also supports low-VOC goals.

Example: bonding a solar glass layer to a frame. The resin holds fast, stays clear, and speeds lamination flow. In sensor pods, it seals fine gaps without heavy heat.

Sustainability note:

Ask this simple question: Can a short, focused cure replace a long oven bake? If yes, both cost and footprint may drop.

UV-curing helps makers build faster, cleaner, and brighter. It protects delicate parts, supports mixed materials, and improves line flow. From tiny boards to large panels, joints reach handling strength in seconds. Clear bonds stay neat and resist daily stress. Teams gain traceable settings they can repeat with ease. With the right resin, lamp, and process logs, you can enhance yield and maintain design flexibility. Small changes at the joint can significantly improve the overall product.